662c86d17e7a1

662c86d17eb1b

Yarn dyeing

To give uniform dyeing to the complete yarns , we use Cheese dying Fongs machines with Vessel Capacity ranges from 54 Kgs to 1000 Kgs! Our dyeing capacity is 4 tonnes per day with very less water consumption & high efficiency. We achieve consistency of dyed colours.

662c86d17f27c

RF Yarn dryer

We use Italian made Stalam RF Yarn dryer machine for high efficient time saving drying. Fibre damaging in yarn is hugely avoided with this drying!

662c86d17f654

Fabric / Piece Dyeing

All of Cotton, Viscose, Polyester & Poly cotton fabrics can be dyed using our Hydraulic jigger & CPB (Cold Pad Batch) machines.

Hydraulic Jigger - HARISH

We have fully automated hydraulic jigger machines 6 Nos. with the total capacity of 6 tonnes and with PLC Controlled feeding - these runs with high efficiency and less power / water consumption than the conventional fabric dyeing machines. Fabric shade evenness will be great.

Kusters CPB Machine

With this Cold Pad Batch Waterless Salt less & water less Fabric dyeing machine, we get high productivity around 60 mtrs / minute with high dye fixation! Water and energy consumption is very very less!

662c86d17fde4

Garment Washing Machine

We have advanced Ramsons Horizontal Washing Machine (Belly Washer) with Washer extractor and Steam Tumble drier set up! Hot forged end flange shafts ensures long life of both Machine and the washed fabric!

662c86d1800f0

Eco Friendly Pre-treatments

Enzymes which are a class of Proteins and biodegradable are used in pre-treatments such as de-sizing, scouring, Bleaching etc. The removing of size material which incorporated in pre-weaving process is de-sizing and we use Hydraulic method of Enzymatic steep!

662c86d180440

Mercerization

The fabric is passed through drying cylinders to reduce the moisture content of fabric then through cooling station to provide Superior strength improvement, durability of Dimensional stability and soft feel!! We have MENZEL chainless continuous Mercerizer in-house!

662c86d180682

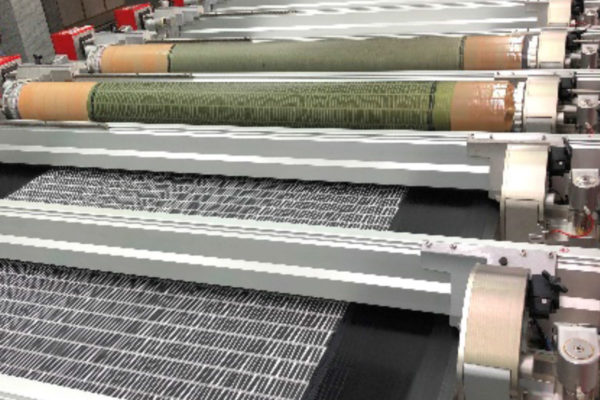

Rotary Printing

We have MHMS Austria made Rotary screen printer which can print 12 colours - 1mtr repeat of any Discharge / Reactive / Pigment printing on Cotton / Polyester / Viscose & Poly cotton fabrics. With Smarlex Laser exposer used for screen making, you will love the print quality of this machine!

662c86d1809b7

Finishing

We have weft straightener (Bianco), coating (Tusker), Stenter (Harish) & Ronson Sanforising Machine by which we can get the optimized shrinkage of fabrics!